Food pumps:

Food pumps are pumps designed in accordance with EU regulations, which make them suitable for use in the food industry.

The special features of food pumps are:

- Roughness of internal surfaces <0.8 µm, in special cases 0.4 µm

- Applied mechanical seals (internal and external) are made in such a way as to ensure hygiene in the process and cleaning of the pump in the CIP system

- The design of the pumps eliminates the possibility of the formation of dead zones – nooks and crannies with complicated access to detergents.

- The casings of the new pumps are made using cold stamping technology from 6.0 mm thick sheets, which guarantees the stability of the pump under changing load conditions and affects the strength of mechanical seals.

- Appropriate selection of materials for welded joints made in a shell of neutral gases and ongoing processing of permanent joints eliminate the formation of a potential difference at the boundary of materials.

- Pump rotors – in most models (except the GA pump) are made in an open design, cast from chromium-

nickel cast steel in a method that allows finishing processes to achieve the declared roughness. All

impellers are statically balanced, which increases pump durability.

Process nozzles

Hygienic fittings are standard, providing both easy installation of the pump in the system and a safe connection according to the DIN standard.

On request, the pumps can be equipped with nozzles according to SMS, Tri-Clamp or flange connections according to DIN.

Engines

Two-pole electric motors powered by 50 Hz alternating current are standard in pumps.

The motors have bearings that level the axial movement of the shaft and a special tip of the motor shaft made of acid-resistant steel, which is also the pump shaft.

All motors installed in the pumps meet the requirements for operation in an environment with high humidity, resistant to splashes when washing equipment from the outside.

In addition, each pump has a specially designed motor guard, which is its additional protection.

The special features indicated by food pumps contribute to:

- Pumped materials do not lose their structure and properties.

- Pumps used in CIP, SIP systems give the absolute best results.

Application of food pumps:

- Bakery and confectionery industry

- Dairy industry, ice cream production

- Meat industry – supply of blood, brines and liquids

- Brewing

- Processing of vegetables and fruits – production of jams and marmalades

- Production of beverages, juices, syrups, concentrates, sugar dissolution

- Distillation, production of wine, alcohol, alcoholic beverages

- Yeast production pharmaceutical industry

- Water, hot water, chilled water

- Fluid Injection in CIP Washers

- Other substances of low viscosity

Sparnuotės siurbliai

Sparnuotės roto dinamiškas siurblys – įrenginys, kuriame besisukantis rotorius perkelia į skystį gaunamą energiją, sukeliant skysčio impulso didinimą ir pakilimą (slėgio pakilimas, sukeliantis šiuo reiškiniu siurblio įėjimo angoje medžiagų įsiurbimą).

Sparnuotės siurbliai skiriasi nuo tūrinių siurblių tuo , kad tūrinis siurblys pompuoja su slėgiu, kurį leidžia pavaros dydis – su beveik nepakitusiu našumu; sparnuotės siurblys pompuoja našumu, kuriuo leidžia pavaros dydis – su mažėjančiu aukščio pakilimu.

Siurblio našumas [Q]

Tai siurbiamo skysčio tūris per laiko vienetą. Kaip taisyklė siurblio našumas išreikštas m³ / val arba l / min

Pakilimo aukštis [H]

Tai charakterizuojantis sparnuotės siurblius parametras –pakeičiantis skysčio greičio energiją į padėties energiją , t.y. aukštį ir išreikštą vandens stulpo [mH2O] metrais.

Galios poreikis [P]

Tai siurbliu darbo metu sunaudojama galia.

Sukimosi greitis [N]

Siurblio veleno apsisukimų skaičius per vieną minutę [aps./min.]

Siurblio patikimumas [η]

Santykis tarp naudingos siurblio galios ir suvartojamos siurblio veleno galios išreiškiamas procentais [%]. Kai siurblys turi didelį našumą, tai jo naudingumo koeficientas yra didesnės vertės negu mažo našumo siurblys.

Siurbimo pajegumai

Sparnuotės siurbliai turi atvirą konstrukciją – sukantys siurblių dalys nesiliečia vienas su kitu – tai palengvina siurblio priežiūrą, bet neleidžia siurbliui įsisiurbti skystį .

Sparnuotės siurbliai turi būti sumontuoti taip, kad dirbtų su įplaukiančia medžiaga (siurblio antvamzdis turi būti žemiau įsiurbiamo skysčio veidrodėlio).

Pasirenkant siurblį reikia atkreipti dėmesį į tai, kad jis dirbs su tokiu našumu, su kuriuo leis jo spaudimas slėgio vamzdyne. Labai gerai, kai siurblio darbo taškas (Q,H) atitinka maksimaliam naudingumo siurblio koeficientui. Viršijus darbo našumo reikšmei, padidėja siurblio galios poreikis ir gali pasireikšti kavitacijos reiškinys siurblio įsiurbimo zonoje ir siurblio viduje.

Sumažinus našumą iki nulio, pvz., didėjantis pasipriešinimas iš įsiurbimo pusės gali iššaukti skysčio kaitinimo reiškinį siurblio viduje.

Sunkiųjų skysčių pompavimas

Pompuojant didesnio lyginamojo svorio skysčius, siurblio pakėlimo aukštis nemažėja, padidėja tik siurblio elektros energijos sunaudojimas dėl padidėjusio slėgio , veikiančio siurblio sparnuotę.

Tačiau labai dažnai nutinka, kad didelio lyginamojo svorio skysčiai tuo pat metu pasižymi klampumo padidėjimu.

Klampiųjų skysčių pompavimas

Didesnio klampumo skysčių pompavimas turi įtakos siurblio darbui. Mažėja jo našumas (Q) ir pakilimo aukštis (H); žymiai didėja siurblio sunaudojamos el. galios (P) poreikis dėl padidėjusio vidinės skysčio trinties, sparnuotės darbaračio ir vidinių siurblio elementų pasipriešinimo.

Didesnio klampumo skysčių pompavimas su pilnu siurblio uždroselinimu skysčio pakilimo aukštį priartina prie vandens pakilimo aukščio. Pompuojamo skysčio našumo didinimas sumažina medžiagų pakilimo aukštį.

Vane pump types:

Vane pump type WPs:

The pump is used for all liquids used in the food industry where there is a small pressure in the system

and a small capacity and lifting height are required.

Pump type GH

The pump is designed for systems where food safety is a very important element.

Transporting food products in liquid state with a viscosity up to 1000 cP, the pump is used in:

- dairy industry (fresh and pasteurized milk, whey, ice cream mixes)

- fruit and vegetable processing (unclarified and clarified juices),

- pharmacy.

Pump type GA

A classic pump that has been used in dairy systems for decades. Reliable in operation, its design and the shape of the inner casing contribute to the long life of the mechanical seal.

The pump is the only vane pump made of AISI 304 steel in the food range. All other pumps are made of stainless steel AISI 316L (1.4404). The pump is equipped with a closed working rotor.

Pump type GU13 and GU14

Pumps designed for the transport of condensed food liquids with a dry matter content up to 50% or other food liquids with similar properties at temperatures up to 95°C.

The pump is equipped with an open impeller. The pump is equipped with a classic soft graphite seal, can work in systems with low vacuum pressure.

Pump type GU15 and GU15/4

The pump is designed to transport non-condensed or thickened food liquids with a dry matter content of up to 50% or other liquids with similar properties at temperatures up to 95°C.

Due to the increased lift height, it can be used when pumping substances through plate, tube heat exchangers or other devices with significant resistance.

Pump type GU-30/30, GU-30, GU-50/15 GU-46, GU-42, GU-50, GU-70

A wide range of vane pumps designed to convey nutrients with a viscosity up to 1000 cP.

- dairy industry (fresh and pasteurized milk, whey, ice cream mixes)

- fruit and vegetable processing (unclarified and clarified juices), juices with pulp, fruit drinks, vegetable drinks, wine, liqueurs),

- distillation (mash, spirits)

- pharmacy

- pumping of basic substances in the food industry (water, purified cold or hot water)

- cleaning liquids for the CIP system and other liquids.

- Lobe pump type PWk

Pump PWk type

Lobe pump with adjustable lobe speed. The pump is a type of volumetric pumps, used for pumping

liquids with high viscosity (up to 10,000 cP) Mayonnaise, ketchup, concentrates, vegetable oil, melted

cheese, yogurt. The pump is capable of pumping soft solids without crushing them.

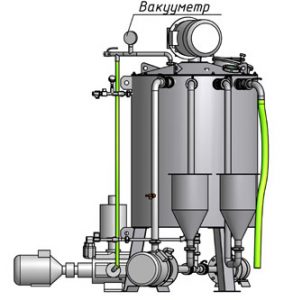

CIP pump type LR

Vane circulation pump.

The pump is not a product pump, it is used in washing systems in the CIP system.

The pump has a large suction capacity of about 7 mH2O and the ability to self-prime the liquid due to

the annular channels in which liquid remains constantly.

Dynamic stirrer type MD

A mechanical agitator is designed to mix several jets of liquid in a stream.

The device is able to effectively mix liquids that aggressively react to each other under environmental conditions – forming gels or releasing a large amount of temperature during mixing. The types of dynamic mixers produced are designed for mixing two or three liquid components.

Four-blade agitator – Homogenizer type H4 is designed to bring to a homogeneous state a liquid prone to sedimentation.

Impeller pump.

An impeller pump with a flexible working element is used when pumping liquids with high viscosity. The impeller pump can be used for pumping a wide range of liquids in the chemical, cosmetic, pharmaceutical, dairy, canning, confectionery, oil and fat industries, etc.

The impeller pump is designed for pumping thick, liquid masses with a viscosity of up to 20 Pas with an admissible inclusion of air and solid particles. Due to the displacement principle, the pump can be used as a dosing device.

Advantages of the impeller pump:

• Wide range of applications in various fields

• Can be used as a dispenser

• Pumping liquids, emulsions, suspensions

• containing small particles (for example, pieces of berries) with

• preserving their structure

• The flow part is made of high quality

• stainless steel, and the impeller can be made

• both from conventional and oil and petrol resistant materials

• Possibility of manufacturing with a heating jacket

• Fast, simple and inexpensive maintenance

The principle of operation of the impeller pump: Pumping occurs due to the rotation of a flexible rubber rotor located in the oval pump housing.Impeller pumps can be made in stationary or mobile versions. The impeller pump has high performance, reliability and long service life.

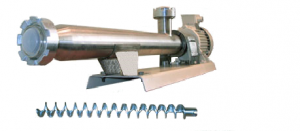

Screw pump

The advantage of a screw pump is that when pumping products with inclusions, there is no crushing and destruction of inclusions (for example, when pumping jams with pieces of fruit).

Execution. The pump is equipped with an end seal made of siliconized graphite (or gland packing). MTBF 5000 hours, temperature up to 120 o C.

Nozzle size Du 50. Operating temperature of the pumped product from -15 to +110 o C, on pumps with stuffing box packing, the temperature of the pumped product is from -5 to + 300 o C.

All parts of the pump that come into contact with the product are made of food grade stainless steel.

For pumping products with maintaining the temperature, the pump is equipped with a heating jacket.